V/P switchover position, a key point for injection molding consistency:-

During the injection phase of the molding process, the primary objective is to swiftly introduce material into the cavity under high pressure, ensuring complete part filling. In the subsequent holding phase, the material undergoes a cooling and shrinking process due to the wonderwall effect, causing it to retract slightly within the mold. To counteract this shrinkage and maintain the desired dimensions, a controlled holding stage is implemented. This stage also includes a crucial transition point called the "switch over position," where material flow shifts from injection to holding.

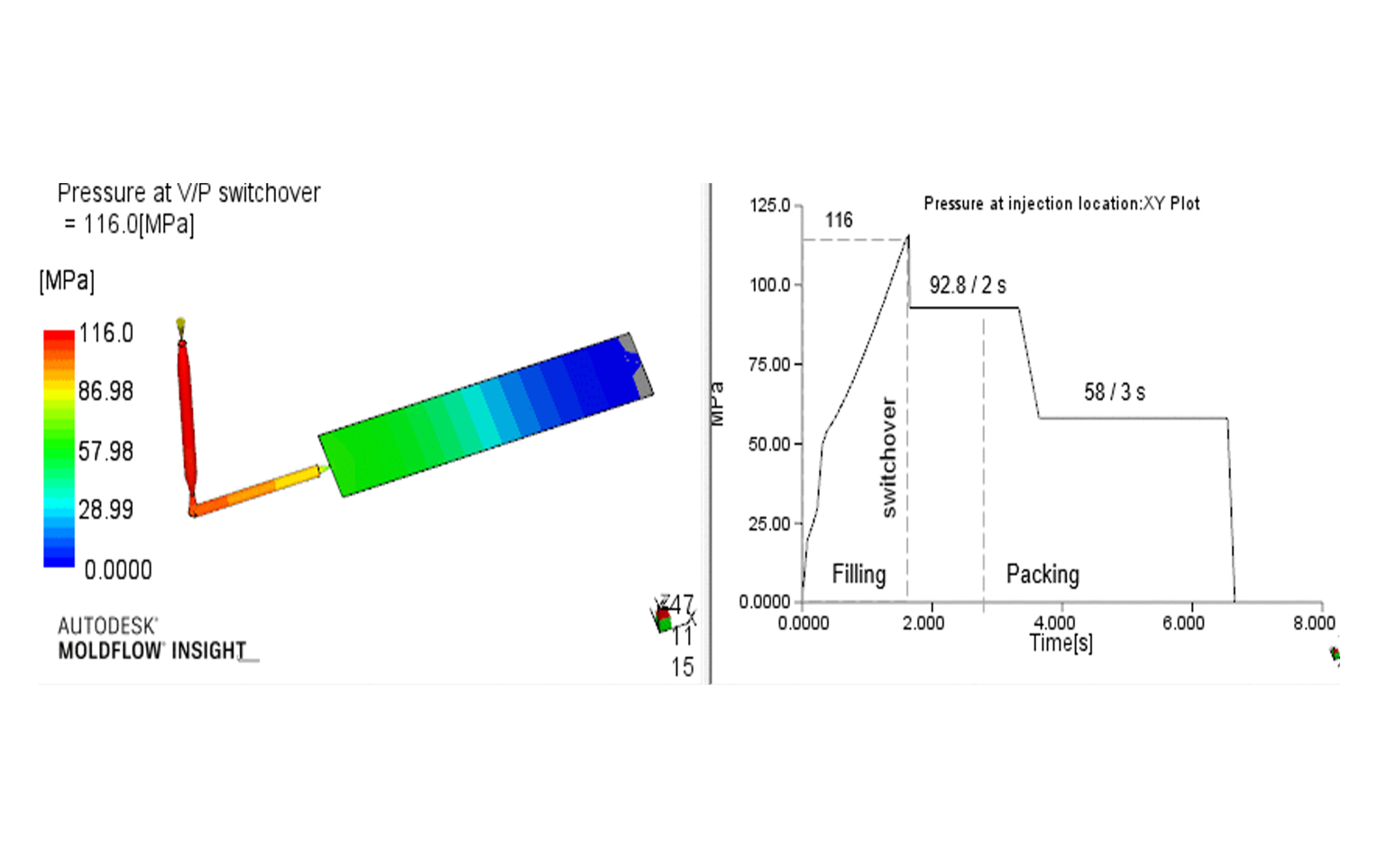

The switch over or V/P switchover position is pivotal as it affects parts consistency. To achieve consistent results from one shot to another, it's essential to inject the part to about 95-98% of its weight during the injection phase. This careful injection approach prevents potential flashing that could occur if the part were filled to 100% and above. If the switch over happens prematurely, the material cools, pressure controll drops, and a loss of flowability occurs.

Determining the switch over position based on part weight, rather than solely its shape, is critical. By monitoring the part's weight using a balance, the optimal moment for switching from injection to holding can be accurately identified.

The duration of the holding phase depends on desired aesthetics and may vary in seconds. It's essential to consider the freezing time of the gate-the entry point for material into the mold. A small, frozen gate can impede material flow even under high pressure, leading to inadequate filling and potential over shrinkage or shrink marks on the final part. Therefore, achieving proper gate freezing and establishing the correct holding parameters are vital for successful part production.

In summary, the molding process involves an injection phase for efficient material introduction and a holding phase to counteract shrinkage effects. The switch over position, determined by part weight, marks the transition between these phases. Careful control of injection percentages, along with attention to holding parameters and gate freezing, ensures consistent and high-quality results in each production cycle.